KUSTERS WATER DIVISION

Headworks | Thickening | Clarification | Biosolids | Odor Control | Biological

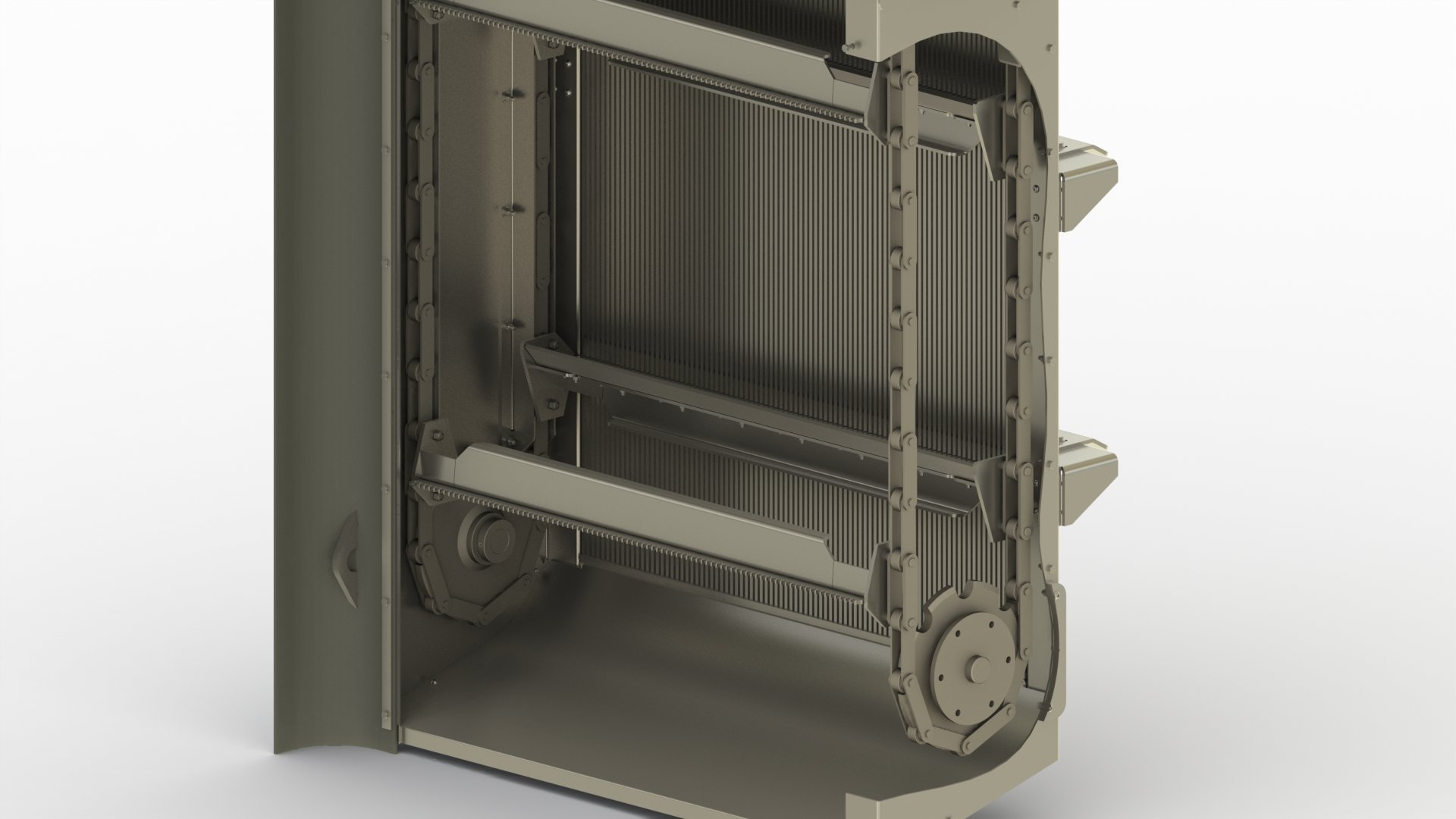

MULTI-RAKE BAR SCREEN

The Kusters Water ProTechtor® Multi-Rake Bar Screen combines fine or coarse screening with high solids capture rates. Its robust construction and overload feature ensure reliable operation.

PRINCIPLE OF OPERATION

Wastewater flows through the stainless steel bars while the non-biological solids, such as paper and plastics, are trapped on the screen face. The screenings are removed from the bars by rakes fixed between two heavy duty roller chains. These rakes utilize laser cut teeth that precisely engage and clean the bars to a depth of 12 mm. In the event an object becomes lodged in the bars, the overload feature enables the rakes to reverse and remove the obstruction then continue cleaning the bar rack.

The screenings are conveyed from the bars over a dead plate, where they have sufficient time to drain, and are discharged at the top of the screen into a dumpster, conveyor or compactor. The Multi-Rake Bar Screen is designed to tightly seal to the walls of the channel to prevent any bypass from occurring and, due to the design of the lower frame, a recess in the floor of the channel is not required.

-

Rugged stainless steel construction

Automatic “jam” reversing

High hydraulic capacity, low headloss

Insensitive to grit and stones

“Maintenance free” bottom bearing, or fixed guide

Dual speed operation

Trapezoidal Bar Design

Replaceable bolt-in bars

US Manufactured (ISO 9001:2015)

3-Year Factory Warranty

-

Municipal sewage treatment plants

Industrial wastewater treatment

CSO screening applications

Wastewater pump stations

Sludge Screening

-

Channel widths from 1 to 12’

Standard channel depths to 40’

Custom channel depths available greater than 40’

Bar spacing from 4 to 100 mm

Standard angles of inclination: 50°, 75°, 80°, 85°, 90° from horizontal